Technical requirements for granite slab design

Technical requirements for granite slab design

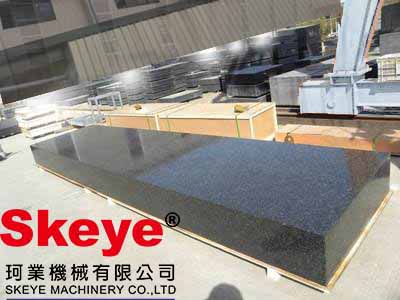

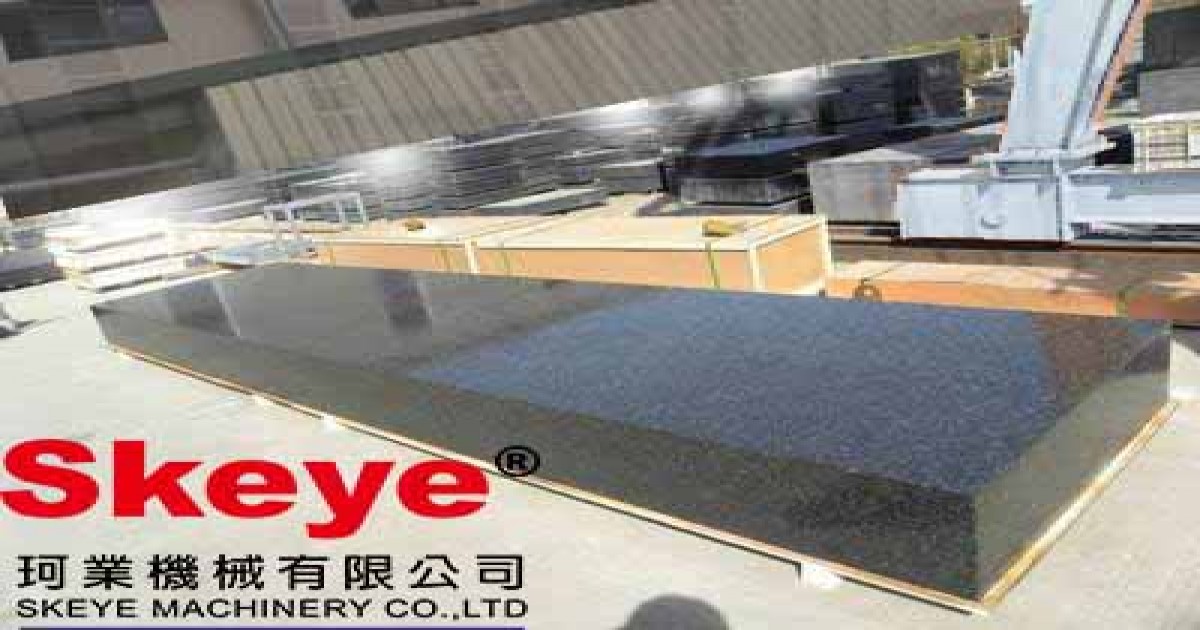

According to actual needs, the technical requirements for the design and production of granite slabs are stipulated. In the national standards, corporate standards and the use requirements of granite slabs, the design and production technology of granite slabs can be requested according to actual needs. The design and production of granite slabs should be based on the principle of making the best products at the lowest cost.

During the production process of granite slabs, a part of the theoretical weight error will occur, but it should be noted whether the production errors of granite slabs affect the normal use of granite slabs. Generally, the design of granite slabs should take into account machining errors and casting errors. Generally, the weight error of granite slabs should not exceed 10%. When it exceeds 10%, we need to re-evaluate the quality of granite slabs. And inspection to determine whether the granite slab can be put into use normally.

There may be some product defects in the production process of granite slabs, as long as the correct process methods are used to make up for repairs. The following are the technical precautions in the production of granite slabs:

⒈The working surface of the granite slab shall not have any defects such as sand holes, shrinkage porosity, scratches, bumps, pores, cracks, slag inclusions and rust that seriously affect the appearance and performance of the granite.

⒉ The dents or corners on the non-working surface of the granite slab are allowed to be repaired.

⒊The perpendicularity tolerance of the side of the granite slab to the working surface and the perpendicularity tolerance of the two adjacent sides of the slab are in accordance with the 12 levels specified in GB/T1184.

⒋ The concentrated load area in the center of the granite slab working face, the applied rated load and the allowable deflection value are specified in Table 3.

⒌ It is recommended not to set up a carrying handle for the level 000 and 00 plates.

⒍ If threaded holes (or grooves) are provided on the surface of level 0 and level 1, the position should not be higher than the working surface.

⒎ The granite slab should be made of fine-grained, densely structured gabbro, diabase, granite (biotite should be less than 5%, elastic modulus should be greater than 0.6 × 10-4kg/cm2, water absorption rate should be less than 0.25 %) and other materials, the hardness of the working surface should be greater than 70HS.

⒏ The maximum allowable value of the surface roughness Ra of the granite slab working surface is 0.32~0.63um, and the side surface is 10um.

⒐ Flatness tolerance of granite slab working face

⒑ When using the diagonal method or the grid method to test the flatness of the flat working surface, the gas plane fluctuation amount and the plane fluctuation amount of the working surface should be checked.