Matters needing attention in the assembly process of stone machinery

[[ Matters needing attention in the assembly process of stone machinery]]

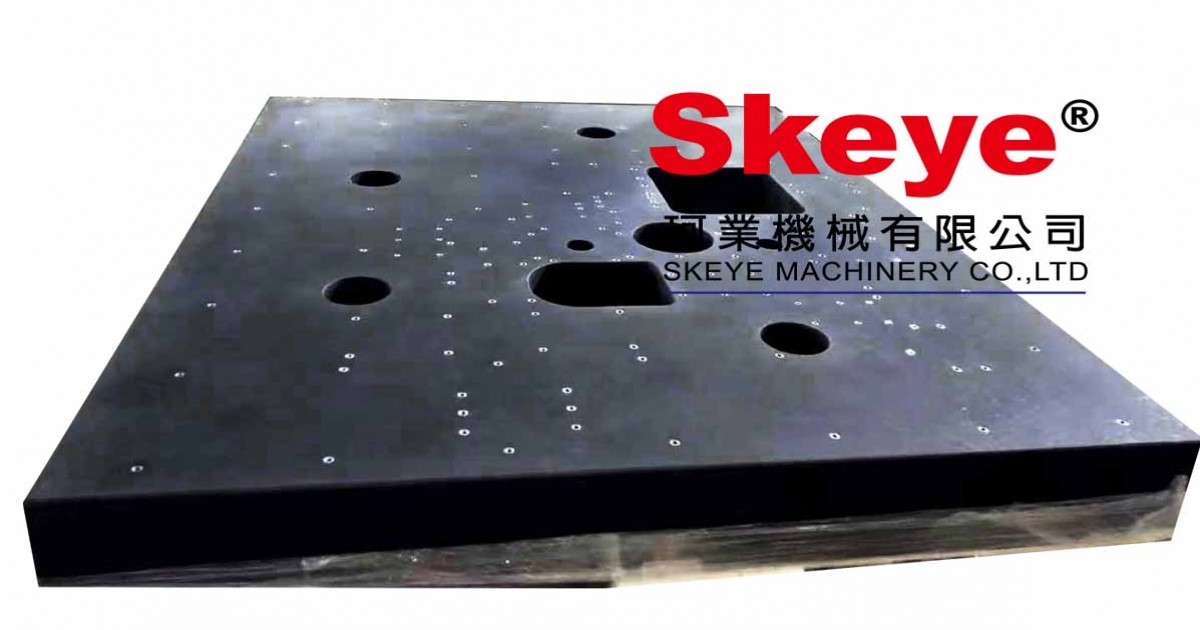

Keye Machinery Company Granite Components

In the industrial revolution, people still used pure hand to mine and process stone. It was known that the first stone processing machine appeared in Europe in the 19th century, which established a new revolution in the stone processing industry. From then on, stone processing began to develop from manual operation to mechanization. With the development of stone processing equipment and processing tools, there are more and more types of stone machinery, followed by large cutting, see-saw, infrared bridge cutting, wire saw, arc board cutting machine, arc board grinder, stone wire cutting machine , CNC engraving machine and a series of material processing equipment.

Although the types are rich and diverse, mechanical equipment manufacturers must ensure the quality of the assembly of stone machinery products and must operate in accordance with the required technical requirements for the assembly of various stone machinery products.

According to the assembly process of several common types of mechanical equipment.

The granite component of Keye Machinery Co., Ltd. summarizes the following precautions:

1. Do a good job of cleaning and cleaning the parts. The cleaning work includes the removal of residual foundry sand, rust, chips, etc.

Especially some important parts, such as the gantry cutting machine, the inner cavity should be painted with anti-rust paint.

Oil stains, rust or attached cuttings on the parts can be cleaned with diesel, kerosene or gasoline as a washing liquid, and then dried with compressed air.

2. Lubricant is usually added to the mating surface before mating or connecting. Especially the bearing part in the spindle box component, the screw nut part of the lifting mechanism.

3. The matching dimensions of the matching parts should be accurate, and the matching dimensions should be re-inspected or spot-checked during assembly. For example: the matching part of the shaft journal and the bearing,

The hole of the spindle box and the bearing and its center distance.

4. The assembly of the wheels requires that the axis lines of the two toothed wheels must be in the same plane and parallel to each other. Normal toothing clearance should be ensured, and the axial misalignment should be ≤2MM.

5. The joint surface of the joint should be checked for smoothness and deformation. Otherwise, it should be trimmed and burrs removed to ensure that the joint surface is in close contact, flat, and not skewed.

6. The seals should be pressed into the sealing groove in parallel, and they should not be twisted or deformed, and the sealing surface should be damaged or scratched.

7. The assembly requirement of the pulley is that the axes of the two pulleys must be parallel, and the center of the groove should be positive. If the deviation is too large, the tension of the pulley will be uneven.

Cause belt slippage and accelerated wear. At the same time, the V-belt should be selected before assembling, and the length should be consistent to prevent vibration in the transmission.

8. The bearing should be cleaned before assembling, and can be assembled after washing and removing the anti-rust paint; when cleaning, check whether the raceway and rolling elements are corroded, and whether the rotation is flexible;

When the bearing is assembled, a layer of lubricant should be applied to the surface of the mating part. If the pressure difference is too large during assembly, the assembly should be stopped for inspection; when assembling the bearing,

The end without a model number should face inward, against the shoulder of the shaft; the magnitude, direction, and position of the applied force should be appropriate when the bearing is set, and the rolling element of the raceway should not be stressed.

It should be hit evenly and symmetrically, not slammed, to ensure that the end face is perpendicular to the shaft to prevent installation tilt.

9. The threaded connection should adopt the anti-loosening device, and the following common anti-loosing devices should be selected according to the actual situation and design requirements; double nut anti-loosing; spring washer anti-loosing;

Split pin anti-loose; stop washer anti-loose round nut and flower washer anti-loose; symmetrical multiple bolt tightening method should be tightened gradually in a symmetrical sequence,

The strip connector should be tightened gradually from the middle to two directions symmetrically. The end of the rib of the bolt connection should protrude from the nut.

10. Do inspection while assembling.

11. Do a good job of pre-driving inspection carefully. For example: check the completeness of the assembly work, the accuracy and reliability of each connection part,

The flexibility of moving parts, the normality of the lubrication system, etc.

12. Do a good job of monitoring the startup process carefully. After the machine is started, immediately observe whether the main working parameters and moving parts are moving normally.

The main working parameters include the speed of the movement, the smoothness of the movement, the rotation of the main shaft, the lubricating oil pressure, the temperature, the vibration and the noise.

Only when the various sports indicators are normal and stable at the start-up stage can the test run.

13. Carry out trial operation according to the acceptance conditions of various stone machinery products, and inspect related items.

For example: the adjustment and test of the cutting speed and stroke, the adjustment of the lifting motion stroke, the test of the spindle rotation accuracy, etc.

Keye Machinery Co., Ltd. High-quality stone machinery is the guarantee for processing higher-quality products.